Introduction to Forklift Operation Safety

Forklift operation safety is a critical aspect of industrial environments where these powerful machines are utilized for material handling. Forklifts are essential in warehouses, construction sites, and manufacturing facilities, enabling efficient movement of goods and materials. However, the benefits of using forklifts come hand in hand with significant risks. Accidents in forklift operations can lead to severe injuries, fatalities, and damages, thereby highlighting the importance of prioritizing safety measures.

According to statistics, forklift-related incidents account for a substantial number of workplace injuries. These incidents can arise from various factors, including operator error, inadequate training, improper maintenance, and environmental hazards. Common risks include collisions with pedestrians, tipping over due to improper load handling, and falling objects, all of which can result in devastating consequences for employees and the organization. The financial implications of such accidents can be significant, ranging from increased insurance premiums and medical costs to potential legal liabilities and productivity losses.

The focus on safety in forklift operations is further underscored by regulatory requirements set forth by authorities such as the Occupational Safety and Health Administration (OSHA). These guidelines mandate that employers provide a safe working environment, which includes ensuring that operators are adequately trained and that equipment is properly maintained. Failing to comply with these regulations can lead to hefty fines, stricter oversight, and damage to a company’s reputation.

In light of these challenges, it becomes imperative to adopt innovative solutions that enhance forklift operation safety. Wireless forklift monitoring systems represent a technological advancement that can significantly reduce risks. By integrating real-time data monitoring, these systems can help track operator behavior, equipment status, and environmental conditions, providing valuable insights to enhance overall safety. As we explore these advancements further, it is crucial to understand the foundational importance of safety in forklift operations.

Understanding Wireless Forklift Monitoring Systems

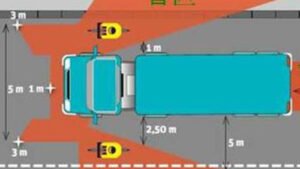

Wireless forklift monitoring systems represent a pivotal advancement in material handling safety and efficiency. These systems employ an array of sensors and communication technologies to track forklift operations in real-time. At the core of these systems lies a network of sensors that gather data on various parameters, such as load weight, operational speed, and even the geographic location of the forklift. This data is then transmitted wirelessly to a central monitoring system or cloud-based platform for processing and analysis.

One of the key technologies utilized in these systems is RFID (Radio Frequency Identification), which helps in tracking forklifts and their loads accurately. Complementing this are various types of sensors, including proximity sensors and tilt sensors, which enhance safety by alerting operators to potential hazards. The data collected by these sensors can also be analyzed to identify trends and inefficiencies, allowing for proactive maintenance and operational improvements.

The functionality of wireless forklift monitoring systems extends beyond mere tracking. They often include features such as geofencing, which allows operators to set virtual boundaries for forklifts, ensuring they do not venture into restricted areas. Alerts can be configured to notify supervisors in real-time when certain safety thresholds are breached, such as excessive speed or tipping risks. Additionally, the integration of GPS technology helps in fleet management, enabling companies to optimize their logistics and resource allocation.

By implementing wireless forklift monitoring systems, companies can significantly enhance the safety culture within their operations. The immediate visibility into forklift performance and safety metrics fosters accountability among operators and encourages adherence to best practices. Ultimately, these systems not only protect personnel and assets but also contribute to an increased operational efficiency through data-driven insights.

Benefits of Implementing Wireless Monitoring Systems

The integration of wireless forklift monitoring systems into operations offers a plethora of advantages that significantly enhance safety and efficiency in any workplace. One of the most critical benefits is the improvement in safety measures. By utilizing real-time data, these systems enable operators and management to monitor forklift activities closely, thereby reducing the risk of accidents and ensuring adherence to safety protocols. For instance, a study revealed that organizations implementing wireless monitoring systems observed a 30% decrease in workplace accidents involving forklifts, showcasing the importance of proactive safety management.

Another vital benefit is the real-time tracking of forklift activity. Wireless monitoring systems allow managers to access essential data regarding equipment usage, operator performance, and maintenance needs instantly. This capability not only aids in effective decision-making but also facilitates timely interventions in case of irregularities. For example, if a particular forklift shows erratic usage patterns, management can investigate further, ensuring that all equipment is operated correctly and safely.

Compliance with safety regulations is further enhanced through the implementation of these systems. Many regions impose strict guidelines on material handling equipment to ensure safety in the workplace. Wireless monitoring systems can assist companies in maintaining compliance by providing insightful data that can be used for audits and inspections. Regular reporting of operational metrics ensures that organizations stay informed about their adherence to safety standards.

Lastly, increased productivity is another significant advantage of wireless forklift monitoring systems. By analyzing operational data, managers can identify bottlenecks and optimize workflows, leading to improved efficiency. In practice, companies that adopted this technology reported a productivity boost of up to 20%, demonstrating how ongoing monitoring can positively impact overall operational performance.

Key Features of an Effective Wireless Monitoring System

The effectiveness and reliability of a wireless forklift monitoring system are determined by several critical features that enhance safety and operational efficiency within industrial environments. One of the most significant aspects is real-time data reporting. This feature allows operators and managers to access current performance metrics and safety data instantly. By providing up-to-the-minute information, businesses can swiftly respond to any issues that arise, reducing the risk of accidents and ensuring optimal operational performance.

Alert systems for safety breaches are another essential component. An effective wireless monitoring system must be equipped to detect hazardous conditions or unsafe operator behaviors. These alerts help in notifying managers and operators of potential risks in real-time, which can significantly mitigate workplace accidents. Implementing such safety protocols fosters a proactive safety culture within organizations and underscores the importance of adhering to safety regulations.

Integration capabilities with existing systems are vital as well. A robust wireless forklift monitoring system should seamlessly connect with other operational technologies already in use within a facility. This integration facilitates streamlined data sharing and enhances workflow efficiency, preventing the need for redundant systems and the complications that arise from managing multiple platforms.

User-friendly interfaces are equally essential, as they ensure that operators can easily navigate the system without extensive training. An intuitive design promotes proper use and minimizes the risk of errors during operation. Furthermore, data analytics capabilities enable organizations to analyze performance trends over time. By identifying patterns and areas for improvement, companies can implement strategies that optimize safety and productivity in their forklift operations.

Installation and Maintenance Considerations

The installation of wireless forklift monitoring systems is a critical step in enhancing operational safety and efficiency. This process demands careful planning and execution to ensure that the systems operate effectively within the existing framework of warehouse management. Typically, the installation involves assessing the specific needs of the facility, including the number of forklifts to be monitored and the areas where coverage is necessary. It is advisable to engage experienced personnel who are familiar with both the technology and the operational requirements of the environment to ensure seamless installation.

Key equipment needed for installation includes the monitoring sensors, wireless transmitters, and a central data processing unit. The sensors are strategically placed on each forklift to collect data on various performance metrics, such as load weight, operational hours, and safety compliance. Wireless communication technology enables these sensors to transmit data in real-time to the central system, allowing for immediate analysis and feedback. Coordination with qualified technicians during installation ensures that all components are correctly configured and integrated with existing safety protocols.

Once installed, ongoing maintenance of the wireless forklift monitoring system is essential to maintain its reliability and effectiveness. Regular updates are necessary to ensure that the firmware and software components are aligned with the latest developments in monitoring technology. Furthermore, troubleshooting common issues, such as connectivity disruptions or sensor malfunctions, should be part of routine maintenance checks. Training staff on the use and importance of the monitoring system fosters a proactive safety culture and enhances operational efficiency. Through diligent installation and consistent maintenance practices, organizations can maximize the benefits of wireless forklift monitoring systems, thereby significantly improving safety measures in forklift operations.

Real-World Applications and Case Studies

As the industrial landscape continuously evolves, numerous companies are embracing wireless forklift monitoring systems to optimize safety and operational efficiency. Prominent sectors such as warehousing, distribution, and manufacturing have showcased the tremendous potential of these advanced technologies through various case studies. One notable example is XYZ Logistics, a leading player in supply chain management that integrated a wireless monitoring solution within its fleet of forklifts. Following implementation, XYZ Logistics recorded a significant 30% reduction in workplace accidents, attributed to enhanced visibility and real-time data reporting on operator behavior and equipment status. This remarkable improvement not only reinforced safety protocols but also bolstered employee morale, leading to a more productive environment.

Another illustration of effective wireless forklift monitoring can be found at ABC Manufacturing, which faced persistent challenges with equipment downtime and inefficient resource allocation. By adopting a comprehensive monitoring system, ABC Manufacturing was able to track forklift utilization metrics, maintenance schedules, and operator performance. As a result, the company reduced its maintenance-related downtime by 25%, contributing to a substantial increase in overall operational efficiency. The seamless integration of this technology also resulted in financial savings by allowing for more informed decision-making regarding training and fleet management.

Furthermore, DEF Retail utilized wireless forklift monitoring as part of their commitment to sustainability and waste reduction. The system enabled them to analyze fuel consumption and optimize logistical routes within their warehouses. Over a year, DEF Retail managed to lower fuel costs by 15%, contributing to their corporate social responsibility goals. These real-world applications exemplify the multifaceted advantages of wireless forklift monitoring systems, encompassing improved safety records, heightened operational efficiency, and considerable financial benefits. The compelling results from these case studies serve as a powerful testament for organizations contemplating the integration of similar monitoring technologies.

Regulatory Compliance and Standards

In the realm of material handling, adherence to industry regulations and standards is paramount for ensuring safety and operational efficiency. Organizations must comply with guidelines set forth by governing bodies such as the Occupational Safety and Health Administration (OSHA) in the United States, which outlines regulations specifically aimed at forklift safety. These regulations govern equipment operation, maintenance, operator training, and accident prevention measures. A thorough understanding of these requirements is vital for any business that employs forklift operations.

Wireless forklift monitoring systems play a crucial role in helping businesses meet these legal obligations. By implementing these advanced systems, organizations can significantly enhance their ability to track and manage forklift usage, operator performance, and vehicle health. Wireless monitoring technologies enable real-time data collection and analysis, allowing for proactive measures to be taken when safety compliance is at risk. For instance, operators can be monitored for adherence to safety protocols, reducing the risk of accidents and ensuring that operational practices are in line with regulatory expectations.

Moreover, these systems facilitate comprehensive documentation and reporting, which can be essential during safety audits or inspections. Accurate records detailing the condition of forklifts and operator training compliance can demonstrate to regulatory agencies that an organization is taking the necessary steps to uphold safety standards. This proactive approach not only aids in adhering to legal requirements but also fosters a culture of safety within the workforce.

Failure to comply with these regulations can lead to significant penalties, legal action, and reputational damage. Therefore, it is imperative for businesses to integrate effective safety solutions, such as wireless forklift monitoring systems, to ensure ongoing compliance with the ever-evolving landscape of industry standards. By doing so, organizations not only protect their assets but also contribute to a safer working environment for all employees.

Challenges and Solutions in Implementation

Implementing wireless forklift monitoring systems introduces several challenges that organizations must navigate to achieve optimal safety and efficiency. One significant challenge is user resistance. Employees may fear job displacement or feel apprehensive about adapting to new technologies. To overcome this resistance, companies should engage workers early in the implementation process, emphasizing the benefits of monitoring systems. Training sessions can facilitate a smoother transition, empowering staff members with the knowledge needed to effectively utilize the new technology.

Another common challenge stems from technical difficulties during the installation and integration phases. Wireless systems depend heavily on reliable network coverage and compatibility with existing equipment. Organizations should conduct thorough assessments of their current infrastructure before implementation. Partnering with experienced vendors can streamline this process, as they can provide insights and support tailored to the specific operational environment. Adequate planning and pilot testing can help identify potential pitfalls, thus minimizing disruptions during full-scale deployment.

Budget constraints also pose a significant barrier to the adoption of wireless forklift monitoring systems. When funds are limited, companies might hesitate to invest in new technologies despite their long-term benefits. To address this issue, organizations should consider phased implementation strategies, enabling them to spread costs over time. Additionally, presenting a well-structured business case that outlines the potential return on investment and expected safety improvements can help secure necessary funding. By addressing these challenges systematically and proactively, organizations can facilitate a successful transition toward a safer and more efficient operation through wireless forklift monitoring systems.

Future Trends in Forklift Safety Technology

As the logistics and warehousing industries continue to evolve, the pursuit of safety in forklift operations is being revolutionized by emerging technologies. Beyond wireless forklift monitoring systems, several trends are reshaping the landscape of forklift safety. One prominent trend is the adoption of automation in material handling. Automated guided vehicles (AGVs) are becoming increasingly common, allowing for the reduction of human error in operations. These systems can operate independently, adhering to predefined paths and schedules, thereby minimizing incidents related to human oversight.

In addition to automation, artificial intelligence (AI) is making significant strides in enhancing forklift safety. AI-driven analytics are being integrated into forklift operations, providing real-time insights into operational patterns and potential hazards. By analyzing vast amounts of data, these systems can predict unsafe conditions before they escalate into accidents. For instance, AI can recognize when a forklift is approaching a high-traffic area and alert operators, enhancing situational awareness and reducing risks.

Another vital development in forklift safety technology is improved telemetry. Advanced telemetry systems are being designed to monitor not just the operation of the forklift itself but also environmental factors such as temperature, humidity, and vibration. This holistic view allows for comprehensive monitoring of the conditions surrounding forklifts, potentially identifying conditions that may contribute to accidents. Systems leveraging enhanced telemetry can send alerts when conditions deviate from safety norms, prompting preemptive actions to mitigate possible hazards.

Moreover, advancements in training and compliance solutions are becoming integral to forklift safety practices. Virtual reality (VR) training programs are emerging, offering immersive learning experiences for operators to practice in simulated environments. This innovative approach enhances operators’ preparedness for real-world scenarios, ultimately reducing the likelihood of incidents caused by insufficient training.

In conclusion, the future of forklift safety technology appears promising with the integration of automation, AI-driven analytics, and enhanced telemetry. These advancements hold the potential to significantly improve safety and operational efficiency, transforming how the warehousing and logistics sectors approach forklift operations and risk management.